Managing inventory is one of the biggest challenges for retail businesses. Your business can have hundreds of SKUs to keep track of throughout the year. And, few business owners know what inventory turnover is and why it’s important. The costs associated with slow turnover or dead inventory go beyond the purchase price of the products. Every day a product sits on the shelves the holding costs decrease the value of the item, and you lose money on your investment.

Calculating Inventory Turnover

One of the best ways to know if your inventory is profitable is to calculate the turnover ratio. This ratio tells you if your inventory is moving too slow or flying off the shelves. With a low ratio, you can adjust your product offering to increase it. If it’s too high, then you’ll need to see if it’s hurting your operations or customer experience.

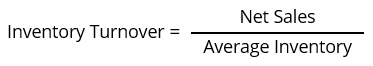

There are several ways to calculate your turnover ratio. The simplest is to divide your net sales by the average inventory:

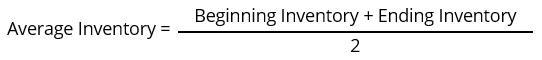

To calculate your average inventory, simply add your beginning inventory with the ending inventory for the entire year, then divide by 2:

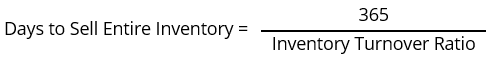

To calculate how many days it takes for your business to turnover the entire inventory, divide 365 by the inventory turnover ratio:

Here’s a good example. Let’s say your Net Sales were $1 million and the Average Inventory was $600K. Your inventory turnover was 1.67 – a very low number – which is not good, because it took 219 days to turnover your entire inventory.

Even though you made a gross profit of $400K, your holding costs are stripping away your profit. All of the costs associated with housing your inventory, including obsolescence and breakage, are considered your holding costs. With every day that passes, these costs take a bite out of your profits. In order to lessen the effects of holding costs, your turnover rate needs to find that “sweet spot,” where it’s not too low and not too high. A high turnover rate may indicate a lack of inventory to cover sales, which reflects poorly upon your ability to deliver products in a timely manner.

How to Fix Your Turnover Rates

There are several ways to fix your turnover rates. Here are some easy steps to organize your inventory and improve turnover.

- Increase Demand – If your products aren’t selling, create marketing activities and promotions to drive sales.

- Pricing – Investigate market pricing on the products you sell and make sure yours are competitive.

- Top Sellers – Focus on what sells and eliminate obsolete products. Dead stock reports are especially helpful for this.

- Sales Reporting – Create sales reports to help with your forecasting.

- Vendors – Work with your vendors to decrease the size of your receivables, which will increase your turnover.

Cloud-based applications, such as point of sale software, can analyze your inventory and sales, helping you increase efficiency with order lead times, delivery schedules, and product lines. With an automated inventory system, you can avoid costly issues, like back orders and returns.

Successful store owners rely on point of sale and retail management software to organize their stock room and improve productivity. To meet the needs of their customer, they know which products to stock their shelves stocked. Meeting your customers’ needs means higher customer satisfaction and continued sales growth.